Plastic thermoforming: Thermoformed parts for businesses

Plastic thermoforming process for a wide range of industries.

More than 1,100 satisfied customers worldwide

We go above and beyond to make your story a success story.

Excellent thermoformed parts that cover every need

We have been producing plastic molded parts for a wide range of applications for decades.

Parts for all use cases

- Buses

- Caravans

- Aircrafts

- Shipping and Transport

- ... and much more

Benefits plastic thermoforming

The advantages of the plastic thermoforming process over injection molding are obvious.

These include the cost factor of vacuum thermoforming plastic, weight-saving options, high and customizable accuracy of fit and reduced production time.

Conclusion: The thermoforming advantages outweigh the injection molding process.

Plastic thermoforming materials

ALDINGER INDUSTRIES specializes in vacuum thermoforming plastics and works with a wide variety of materials such as polystyrene (PS), acrylonitrile butadiene styrene plastic (ABS thermoforming), polycarbonate (PC), polymethyl methacrylate, polyethylene (PE) & polypropylene (PP).

ISO EN 9100:2018 qualified

We are ISO EN 9100:2018 qualified and listed in the OASIS database of IAGQ.

According to the American standard SAE AS 9100/9110/9120 and JISQ9100 (Japan, Asia).

Eco-friendly production

To cope with the change, we greatly emphasize a more sustainable production.

For instance, we produce our electricity and recycle our waste.

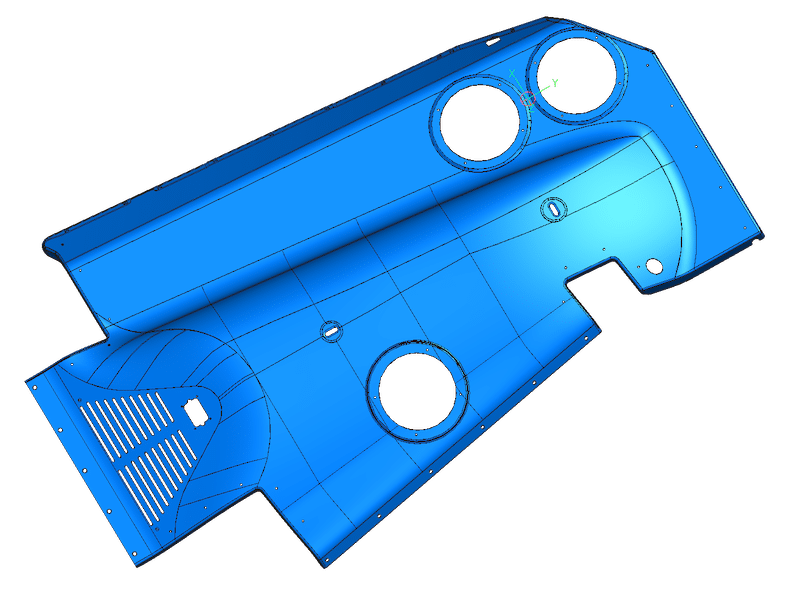

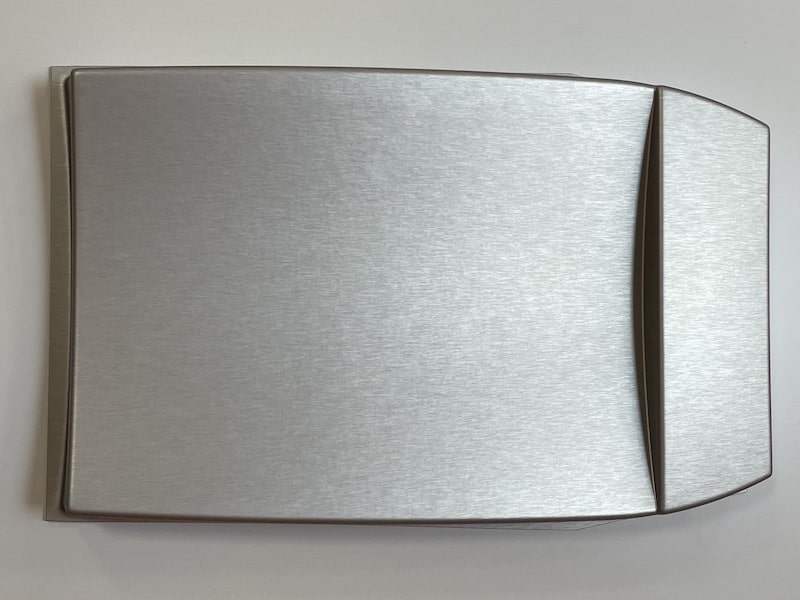

Countless possibilities for thermoformed plastic parts

A series of examples of possible thermoformed plastic parts, shapes, designs and products.

Thermoforming: Unique characteristics

What makes our thermoformed plastic parts unique.

Finishing

Realize parts such as carbon look, wood decor, or individual designs.

Durability

Produce resilient parts that are scratch-resistant and meet strict fire safety requirements.

Chemical resistance

Use special cleaning and disinfecting products on your molded parts.

Haptics

Get surfaces that are not only smooth but also haptically modified if needed.

Plastic and metal

Provide us with your plastic or metal requirements, as we can handle either.

Cleanability

Clean surfaces of parts effortlessly that, for example, have been soiled by markers or liquids.

Plastic thermoforming process in detail

Explanations, technology and applications for plastic thermoforming.

Our thermoformed plastic parts are not only cost-efficient, but are also ideal for a wide range of applications thanks to their fast production time and high-quality materials.

By combining many years of experience with state-of-the-art technology, we ensure that every thermoformed part meets the highest quality standards.

As a deep-drawn parts manufacturer, we specialize in high-quality deep-drawn plastic parts that cover a wide range of applications in various industries. Our expertise in the field of plastic thermoforming parts stands for precision and quality.

Visit our application pages, such as aircraft, logistics, e-mobility, buses, caravans and motorhomes, to find out more about the wide range of possible applications for our deep-drawn parts.

Whether you need prototypes or series products, our thermoformed plastic parts offer the optimal solution for your needs. We pride ourselves on offering our customers individual and efficient solutions that are tailored precisely to their requirements.

Not every material can be used for sophisticated thermoformed plastic products.

Common thermoplastics, often simply described as thermoforming plastic material, are particularly suitable for the production of thermoformed plastic parts, such as:

- PS (polystyrene)

- ABS plastic (acrylonitrile butadiene styrene plastic) (ABS thermoforming)

- PC (polycarbonate)

- PMMA & PET (polymethyl methacrylate)

- PE (polyethylene) &

- PP (polypropylene)

Surface finishes and coatings can be customized and there are theoretically no limits.

At ALDINGER INDUSTRIES, we set ourselves the standard of producing only the highest quality plastic deep-drawn parts for a wide range of industries.

Parts that act as thermoforming examples:

- Cladding parts

- Workpiece carriers

- Seat shells

- Sovers

- Tubs

Thermoformed plastic parts have been part of our DNA for decades. Regardless of whether large or small series or prototype production.

Tools form the basis for successful plastic thermoforming and professional plastic thermoformed parts. We use surfaces and have low tool costs.

This means significantly reduced prices for you, from prototypes to large quantities – compared to injection molding.

The applications for plastic thermoforming are very diverse and must fulfill a wide range of requirements, but thermoforming products exist for almost every conceivable industrial sector.

The most common thermoforming plastic products include:

- Cockpit lining for airplanes

- Seat components with low weight

- Workpiece carriers for safe transportation

- Various packaging components

- Reusable / disposable trays

- Components for heating systems

- Rear light carriers for caravans

Furthermore, there are also special and individual plastic thermoforming products for special industries such as ready-to-install wet cells for motorhomes, various covers in the heating and sanitary sector and almost infinite areas of application and possibilities.

Thermoformed plastic from ALDINGER INDUSTRIES - versatile and used in numerous products

Plastic thermoforming describes the process of forming plastic and is also known as vacuum forming, and thermoforming.

In the thermoforming process, either a roll or moldable plastic sheets are used as the raw material. Automatic roll forming machines are used for thinner material thicknesses and usually work fully automatically.

The plastic is stretched from the roll and shaped using heat and pre-tensioning. It is then demolded, cooled, trimmed and reworked.

Sheet machines are used for the production of large components and thicker material thicknesses. They can be loaded manually or with the help of robots and have longer processing times.

Plastic deep-drawn parts with different plastics can be used in a variety of ways and are indispensable in a wide range of industries, including the aircraft, automotive and rail industries, as well as logistics.

For manufacturers of deep-drawn parts, there are two deep-drawing processes: Automatic roller machines and plate machines.

Deep drawing with automatic rollers:

- Suitable for thinner material thicknesses

- Fully automatic operation

- Plastic is stretched from the roll, heated, pre-stretched, formed, demolded, cooled, trimmed and reworked

Deep drawing with sheet machines:

- Suitable for large-volume components and thicker material thicknesses

- Manual or automatic placement possible

- Longer processing times compared to roll thermoforming

The vacuum forming process offers a number of advantages that elevate it above conventional forming techniques. Here we list some of the notable benefits that make vacuum forming using a dedicated vacuum forming machine the industry’s first choice:

- Unsurpassed precision: the vacuum forming process offers unparalleled precision, delivering accurately formed components with minimal tolerances. This feature is particularly valuable in industries where accuracy is paramount, such as aerospace.

- Material preservation: Unlike traditional methods, which can put undue stress on the material, the vacuum forming process minimizes material thinning and maintains structural integrity. This extends the life of components and increases the overall durability of the product.

- Complex geometries: Vacuum forming is excellent for forming complex geometries that would otherwise be difficult to achieve with conventional methods. This capability opens up opportunities for innovative product designs and functionalities.

- Cost efficiency: By reducing the need for extensive post-processing and surface finishing, vacuum forming streamlines production processes, resulting in lower costs and reduced time to market.

- Improved surface quality: The absence of folds, cracks and other defects ensures superior surface quality and in many cases eliminates the need for additional surface treatments.

The art of thermoforming plastic is a technique within the group of thermoforming processes, also known as hot forming.

The process of thermoforming plastic takes place in thermoforming machines, which are available in various sizes. The size of the resulting thermoformed plastic parts depends on the size of the thermoforming machine used and the required dimensions of the plastic sheet.

Thermoforming of plastic can be carried out in different ways. In one approach, a plastic sheet is heated until it is soft and malleable. Pressure is then applied to deform the plastic sheet using a mold (for example, a model of the intended housing). This causes the plastic to take on the outer contours of the mold due to the heating. After cooling, the mold produced retains the contours of the shape and can then be further refined.

The second method involves pressing the heated plastic sheet onto the mold until the desired shape is achieved.

The choice between these methods depends on the specific characteristics of the thermoforming machine used.

We tailor our products to your needs

What you can expect from working with ALDINGER INDUSTRIES.

All-in-one solution

Assemble the finished thermoformed part into complete modules, all from one supplier.

Variety of materials

Order thermoformed parts made of plastic and modules made of metal, GFK, and much more.

Unlimited scalability

Produce without limitations: from prototypes to mass-produced parts.

High quality

Get high-quality parts thanks to decades of experience, backed up by ISO certifications.

Selectable surfaces

Obtain parts with a wide variety of surfaces and designs, according to your requirements.

Fast results

Fulfill your urgent orders in the fastest possible time.

Need more information?

Frequently asked questions and answers about deep drawing.

Deep drawing or thermoforming is a process for shaping plastics, aluminum, metal and more for the manufacture of customized products.

At ALDINGER INDUSTRIES, one of the leading plastic thermoforming companies, we focus on the production of thermoformed plastic parts.

When thermoforming plastics, plastic rolls or sheets are heated and formed in an aluminum tool.

Vacuum forming, also known as thermoforming, or vacuum thermoforming, is a manufacturing process in which plastic materials are formed into a specific shape.

Similar to other thermoforming processes, vacuum forming involves heating a plastic sheet and then drawing it around a single mold using a vacuum effect.

As thermoformers, we are able to produce all kinds of aircraft, bus, train, logistics and heating and sanitary components.

Plastic components have great advantages due to their excellent price-performance ratio.

On the one hand, they are resistant to chemicals and water, impact-resistant and therefore have a long service life. Thanks to low tooling costs, components are also economically very attractive in smaller quantities.

In addition, the components are generally lighter than alternative injection-molded parts, which means that the overall weight of the systems or the end product is lower, which is becoming increasingly relevant for transport, assembly, installation and use.

Deep drawing, often referred to as thermoforming, involves the shaping of plastics. The process is essentially as follows:

- A plastic sheet is heated until it becomes thermoformable.

- Once it has been heated sufficiently, the sheet is drawn over a special tool using a vacuum.

- As soon as the sheet has assumed the desired shape, it cools down to below the deformation limit.

- The result? The plastic retains the shape of the tool and presents the final shape, either in the form of a roll or a sheet. Thermoforming plastic with roll machines for thinner material thicknesses usually works fully automatically and follows the regular plastic thermoforming principle.

The plastic is stretched from the roll, heated, pre-stretched, formed, demolded, cooled, trimmed and reworked. Cutting machines are suitable for large components and thick material thicknesses. They are fed manually or with robots and have longer processing times.

Various materials can be used for deep drawing. Some examples are:

- Aluminum

- Sheet metal

- Plastic

- Copper

- Titanium

Plastic thermoforming currently closes the gap between the established injection molding process and 3D printing, which is still unreliable and not suitable for mass production.

In principle, all conceivable shapes in which plastic can be thermoformed are possible with very few restrictions.

The quality of the thermoformed part is further optimized through production techniques, tool design and special components.

A wide variety of plastics can be used for thermoforming plastic. For example, the following materials:

- PS (polystyrene)

- ABS plastic (acrylonitrile butadiene styrene plastic) (ABS thermoforming)

- PC (polycarbonate)

- PMMA & PET (polymethyl methacrylate)

- PE (polyethylene) &

- PP (polypropylene)

Other materials such as sheet metal, copper, titanium or aluminum can also be thermoformed – however, ALDINGER INDUSTRIES does not offer these options.

PVC deep drawing is possible without any complications.

PVC-U in particular is formed in the temperature range between 110 °C and 180 °C (e.g. bending, deep drawing). However, forming should not be carried out at temperatures between 140 °C and 165 °C, as ductility is very limited in this range.

With the right thermoforming system or thermoforming machine for plastic, producing parts in both small batches and large quantities is no problem.

ALDINGER INDUSTRIES uses the vacuum thermoforming process to manufacture plastic parts, in which a plastic is usually heated and formed in a mold.

Thermoforming plastics is a popular method for producing individually shaped plastic parts for various industries.

In addition to the unbeatable cost factor and the individual formability of the plastic parts, the long durability is another argument in favor of the thermoforming plastic process.

Plastic thermoforming offers considerable advantages over GRP and injection molding, making it a preferred method in plastics processing:

- Cost efficiency: plastic thermoforming turns out to be particularly economical. While both GRP for large quantities and injection molding for small quantities are not optimal in terms of price, plastic thermoforming at ALDINGER INDUSTRIES guarantees an outstanding price-performance ratio regardless of the series size.

- Lightweight with stability: Thermoformed plastic components produced by thermoforming are not only lightweight, but are also equivalent to injection molded parts in terms of weight. GRP lags behind due to the heavier starting material. However, the plastic parts from ALDINGER INDUSTRIES that are produced by thermoforming not only score points for their low weight, but also for their remarkable stability.

- Precise processing: Plastic thermoforming at ALDINGER INDUSTRIES is characterized in particular by its precise production. Our deep-drawn parts offer an exact fit and thus set standards in production by easily surpassing the manufacturing accuracy of GRP.

There are two approaches to the production of thermoformed plastic parts.

Positive forming and negative forming.

In the positive forming of plastics, the inside of the deep-drawn part is formed. In this thermoforming process, the shape is determined by shaping the outer contour.

In the negative forming of plastic molded parts, the molding is carried out on the inner contour. Dimensioning and molding accuracy are carried out on the outside.

ALDINGER INDUSTRIES uses both positive and negative molding for the production of individual plastic molded parts. We are absolutely flexible in production.

Plastic thermoformed parts are becoming increasingly popular.

A wide variety of industries and sectors are relying more and more on thermoformed plastic parts.

Examples of this can be found in the aviation industry, trains, the automotive industry, sanitary engineering, the logistics and packaging industry, use in trains, buses, motorhomes and electric cars.

Today, plastic components created using the vacuum forming process are used in various sectors, including the aviation industry, logistics industry, sanitary industry and many more. There are practically no limits to the use of such molded parts.

In medical technology, they are particularly relevant due to their ease of cleaning and the associated safety for patients. In vehicle construction, both for passenger cars and commercial vehicles, exterior and interior plastic components are produced using this method.

The thermoforming process has also gained popularity in the machinery and plant sector. In addition to the aforementioned sectors, molded parts made using this process are also used in areas such as packaging, transportation, manufacturing and storage.

The thermoforming process offers us almost unlimited possibilities in plastics processing. Nevertheless, there are some technical limitations in the production of plastic parts.

These result primarily from the machine capacities: The highest achievable part height is 800 mm, the maximum sheet thickness is 13 mm and the machine dimensions are limited to 3000 x 2000 mm.

Despite these restrictions, we can meet all requirements within these specifications.

The costs for your thermoforming project depend on many different factors and cannot be calculated without further information.

We will work with you to create an individual estimate once the scope, complexity and feasibility have been clarified.

By phone at +49 7452 88803800

or by email anfrage.aia@aldingerindustries.com.

Companion of success stories

What our customers are saying about us.