Redefining the making of molded parts

Get simple and complex thermoformed parts that meet your needs.

The many possibilities of our thermoforming process

View samples of possible parts, shapes, and designs.

Unique characteristics

What makes our parts exceptional.

Finishing

Realize parts such as carbon look, wood decor, or individual designs.

Durability

Produce resilient parts that are scratch-resistant and meet strict fire safety requirements.

Chemical resistance

Use special cleaning and disinfecting products on your molded parts.

Haptics

Get surfaces that are not only smooth but also haptically modified if needed.

Plastic and metal

Provide us with your plastic or metal requirements, as we can handle either.

Cleanability

Clean surfaces of parts effortlessly that, for example, have been soiled by markers or liquids.

The manufacturing of your perfectly molded parts

What our manufacturing process looks like.

Raw materials

We store your plastics, as well as all other necessary materials, in our high-bay warehouse.

From there, the parts are transferred directly to the related manufacturing process for further processing.

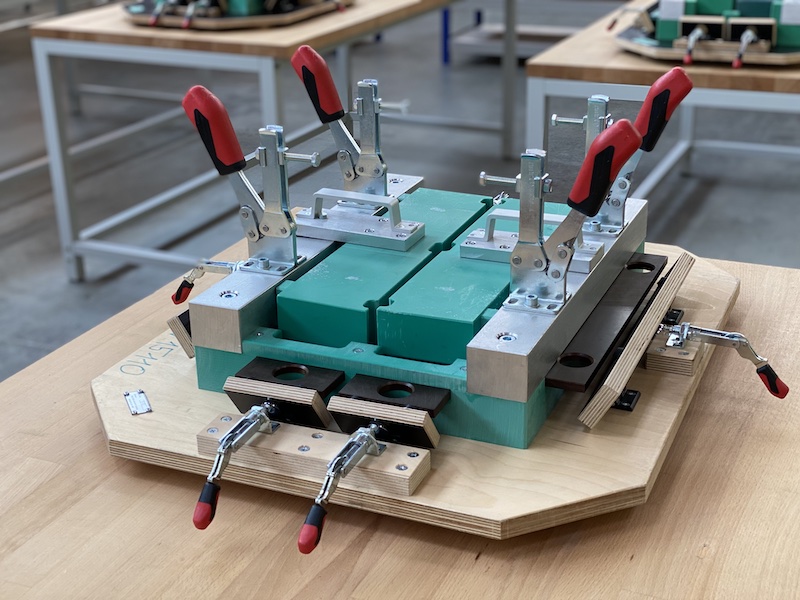

Toolmaking

To react flexibly to your requests, we manufacture our tools based on CAD models.

Starting with the drawing tool, milling fixture, assembly or gluing jig, through to the required measuring program.

Finishing

If required, thermoplastic materials can be finished with our SEE ME by ALDINGER INDUSTRIES method.

This process enables the creation of designs and optical elements, and haptic surfaces, which are generally not available on the market today or only to a limited extent.

Thermoforming

We form thermoplastic materials from 0.8 mm to 10.0 mm thickness on the most modern thermoforming machines up to a maximum size of 2000 mm x 1200 mm x 800 mm.

With a wide variety of controllable heating technologies and various temperature control systems, we guarantee optimal forming while meeting the highest optical demands.

Milling

Using modern computer technology, we program components directly from CAD models.

Afterward, we bring 3- and 2-dimensional components into their final shape on modern 5-axis CNC milling machines.

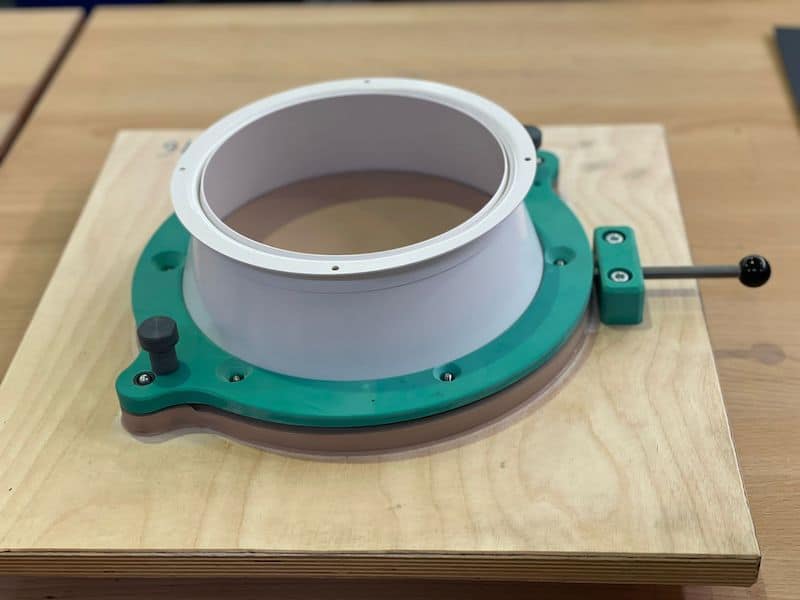

Assembly

In process-oriented assembly lines we manufacture complete modules.

We manufacture the modules with various components from our own production and outsourced parts.

Companion of success stories

What our customers are saying about us.