Plastic interiors tailored to your needs

Approved thermoformed plastic parts for companies.

More than 1,100 satisfied customers worldwide

We go above and beyond to make your story a success story.

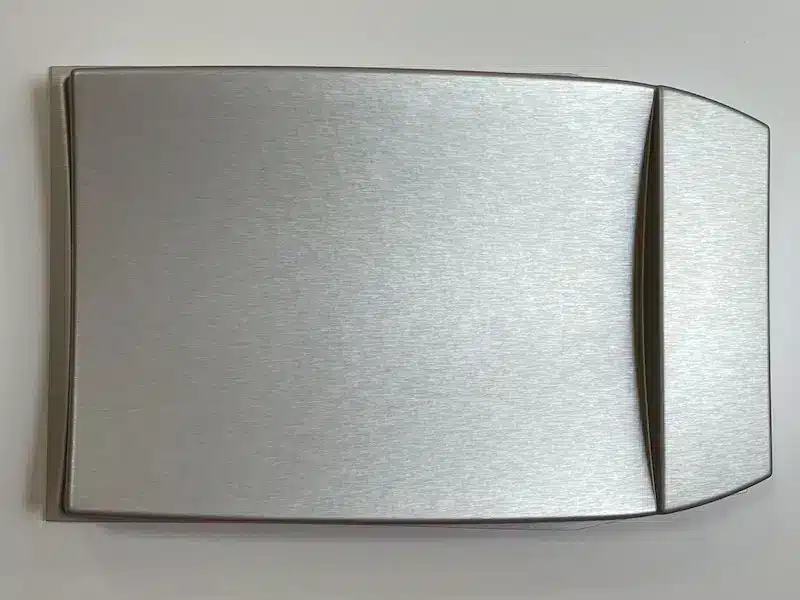

Our vacuum formed interiors

We have been producing thermoformed plastic products for decades.

Example parts interiors

- Armrests

- Backrests

- Cabin parts

- Cup holders

- Luggage compartment parts

Further example parts

- Seat components

- Seat shells

- Storage compartments

- Wet cells

- ... and much more

Excellent parts that leave no wishes unfulfilled

Parts with the features you are looking for.

Reusable and durable

Our plastic interiors are characterized by UV resistance, impact strength, chemical and water resistance.

Accordingly, ALDINGER INDUSTRIES components are ideally suited for long-term applications.

Custom fit parts

For us, compliance with the highest gap dimension tolerance is a matter of course.

This means you have precisely fitting interiors for safe shipping and transport of your products.

Selectable designs

No matter what geometry, we can realize the design wishes of each customer individually.

You can choose from the materials ABS, ABS-PMMA, PE, PS, PS/PE and PVC.

Weight reduction

Weight is playing an increasingly important role, especially when it comes to interior fittings.

Functional surfaces can reduce material thickness and density, resulting in lower weight and costs.

Guaranteed feasibility

We support you already in the development phase of your product to ensure the technical feasibility from the beginning.

This avoids later adaptations and thus high modification costs.

ISO EN 9001:2015 qualified

We are ISO 9001:2015 qualified and live quality in all areas of the company.

Therefore, we ensure our product quality by fulfilling the requirements from DIN ISO 9001:2015 with full commitment.

Eco-friendly production

To cope with the change, we greatly emphasize a more sustainable production.

For instance, we produce our electricity and recycle our waste.

We tailor our products to your needs

What you can expect from working with ALDINGER INDUSTRIES.

All-in-one solution

Assemble the finished thermoformed part into complete modules, all from one supplier.

Variety of materials

Order thermoformed parts made of plastic and modules made of metal, GFK, and much more.

Unlimited scalability

Produce without limitations: from prototypes to mass-produced parts.

High quality

Get high-quality parts thanks to decades of experience, backed up by ISO certifications.

Selectable surfaces

Obtain parts with a wide variety of surfaces and designs, according to your requirements.

Fast results

Fulfill your urgent orders in the fastest possible time.

Need more information?

Frequently asked questions and answers about interiors.

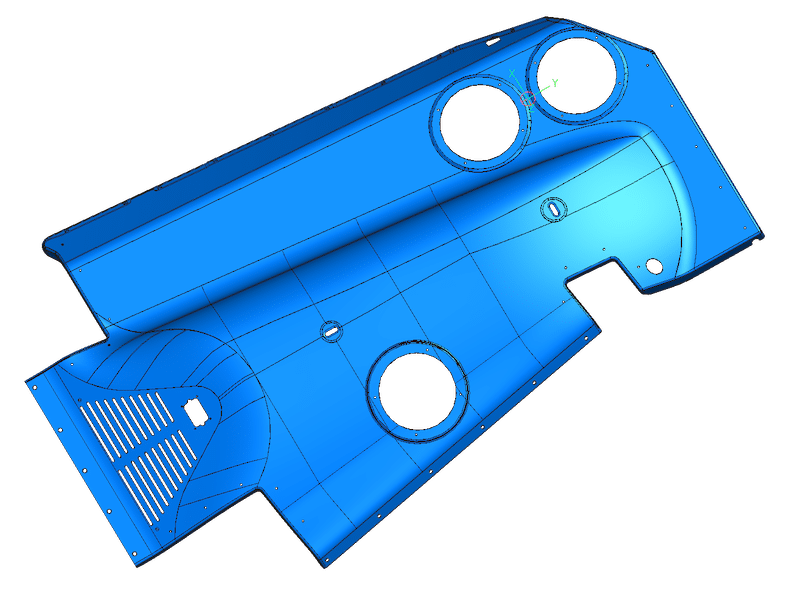

We produce individual, product-specific interiors for all areas.

The backrests, wet cells, armrests and other interiors we produce must meet the highest standards.

Plastic is a much more suitable material for interiors and has considerable advantages over other materials.

In addition to its low price and inexpensive production, it is also lightweight and very stable.

Interiors made of plastic are particularly suitable for indoor applications or for components subject to heavy loads.

The technical characteristics are:

- Dimensions of the molded parts: up to 2000 x 1000 x 620mm

- Materials used: PS, ABS, ABS-PMMA, PS/PE

- Modifications, printing & colors freely selectable

- UV and chemical resistant with high impact strength

Our plastic parts are strong, lightweight, yet cheap and fast to manufacture. We use either new or recycled ABS, PS, PP, PVC or PE plastics.

In the interiors segment, we produce, for example, cabin parts, seat components and cup holders.

We can design other products on demand.

Companion of success stories

What our customers are saying about us.