Plastic components for motorhomes

Interior and exterior components that meet your requirements.

Over 1,100 satisfied customers worldwide

We go the extra mile to make you a success story, too.

Excellent parts that leave nothing to be desired

We manufacture molded parts for motorhome manufacturers and suppliers.

Parts for all use cases

- Wheel housings

- Wet rooms & shower trays

- Cover

- Tail light beams

- ... and much more

Guaranteed feasibility

We support you already in the development phase of your product to ensure the technical feasibility from the beginning.

This avoids later adaptations and thus high modification costs.

Custom fit parts

For us, compliance with the highest gap dimension tolerance is a matter of course.

This means that you have precisely fitting plastic components for the final assembly of your mobile homes.

Weight reduction

We understand that weight reduction is a goal in motorhome construction.

Functional surfaces can reduce material thicknesses, which helps to reduce weight.

High durability

Abrasion resistance and resistance to disinfectants are additional features of our surface technology.

As a result, our ALDINGER INDUSTRIES components are ideally suited for long-term use.

Selectable designs

Class-A surfaces and a wide variety of haptics.

We can realize the design wishes of each customer individually.

ISO EN 9001:2015 qualified

We are ISO 9001:2015 qualified and live quality in all areas of the company.

Therefore, we ensure our product quality by fulfilling the requirements from DIN ISO 9001:2015 with full commitment.

Environmentally friendly production

To meet the changing times, we place great emphasis on more sustainable production.

For example, we produce our own electricity and recycle our waste.

Plastic components for modern motorhomes

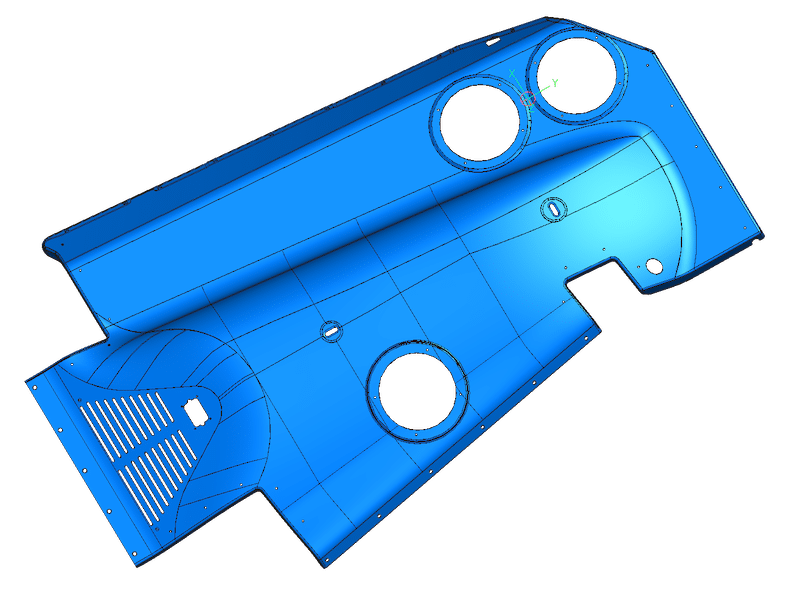

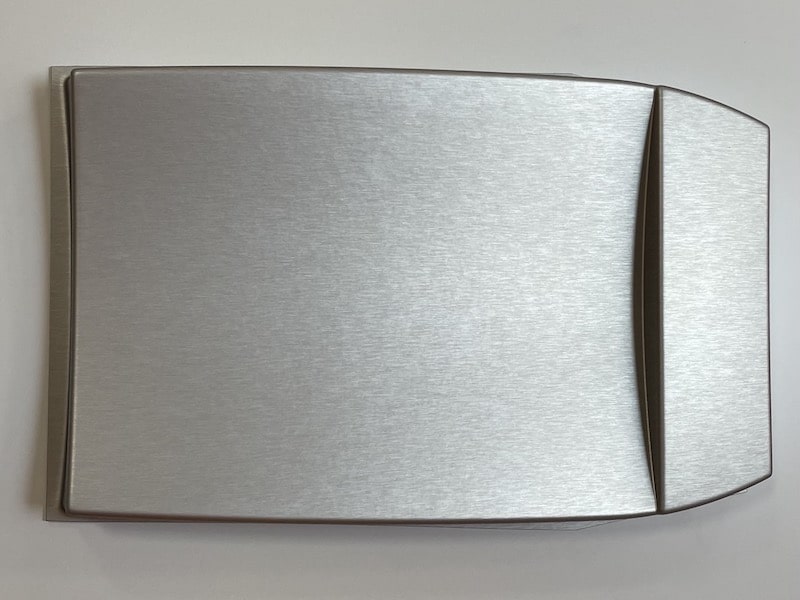

Example components for motorhomes.

Tail light carrier

- Weather and UV resistant material

- For the highest optical requirements

- Outdoor use on motorhome

- Structure Multi-part glued

- Splash-proof

- ABS/PMMA silver or ASA black Material

Shower trays and wet rooms

- Components ready for installation

- For the highest optical requirements

- Use in shower cell / wet cell of the motorhome

- PS, ABS, ABS-PMMA, PS/PE Materials

- Color, shape, embossing, surface finish as you like.

- Mounting options through assemblies, bonding or welding

We tailor our products to your needs

What you can expect from working with ALDINGER INDUSTRIES.

All-in-one solution

Assemble the finished thermoformed part into complete modules, all from one supplier.

Variety of materials

Order thermoformed parts made of plastic and modules made of metal, GFK, and much more.

Unlimited scalability

Produce without limitations: from prototypes to mass-produced parts.

High quality

Get high-quality parts thanks to decades of experience, backed up by ISO certifications.

Selectable surfaces

Obtain parts with a wide variety of surfaces and designs, according to your requirements.

Fast results

Fulfill your urgent orders in the fastest possible time.

You need more information?

Frequently asked questions and answers about motorhome parts.

- Dimensions of the molded parts: up to 2000 x 1000 x 620mm

- Materials used: PS, ABS, ABS-PMMA, PS/PE

- Modifications, printing & colors freely selectable

- UV and weather resistance with high impact strength

ALDINGER INDUSTIRES is able to produce any kind of motorhome parts.

Classics of our production are for example products of the groups motorhome trim, rear light carrier, side skirts, wheel arch covers, drawbar cover, wheel housing shell, wheel trim, B-pillar trim, dashboard, door trim, rear spoiler or also bottle crate covers.

However, we are not bound to these product groups, our portfolio can be easily expanded to include the RV part you want.

As a material for motorhome parts, plastic is much more suitable and has significant advantages over other materials.

In addition to the simultaneously low price and inexpensive production, it is nevertheless light and very stable, which is particularly suitable for exterior parts.

The natural robustness of plastic thus also makes it the ideal material for motorhome interiors.

Depending on the requirements and whether it is for interior or exterior components, we recommend different materials.

For wet cells or shower trays, PS or PS/PE is used, whereas exterior parts such as rear light supports are made of ABS/PMMA or ASA.

Companion of success stories

What our customers are saying about us.